While there are many potential uses for soft-bodied robots, the things are still typically only built in small experimental batches. Scottish scientists are out to change that, with a mass-production-capable soft bot that is 3D-printed in a single piece which then walks off of the print bed.

Before we go any further, this isn’t the first time we’ve heard about a soft robot that was printed in one piece.

It was just this March that we told you about a hexapod bot created at UC San Diego, which was 3D-printed in one continuous 58-hour step. That robot was powered not by a motor but by compressed air, which sequentially moves its legs forward.

The new quadruped robot, designed by scientists at The University of Edinburgh, is likewise air-driven.

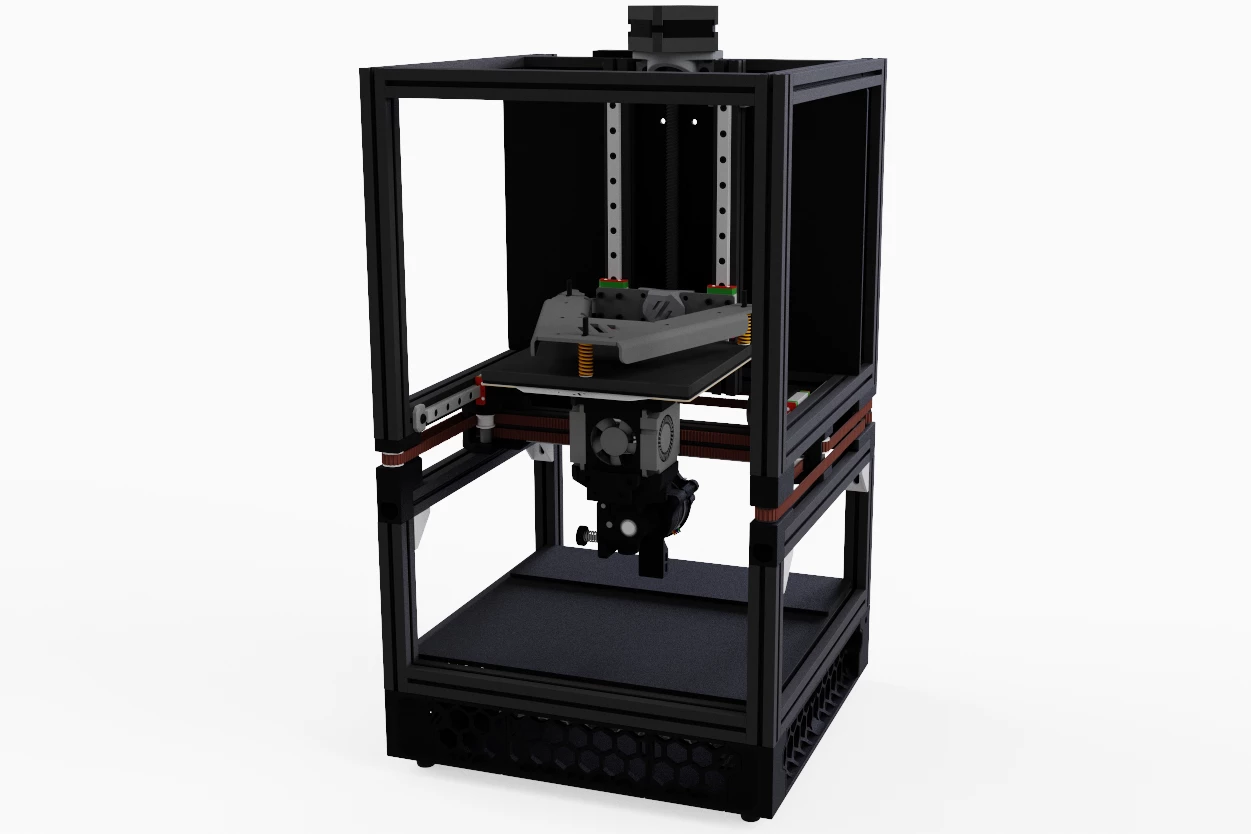

Unlike the UC San Diego bot, however, it “only” takes nine hours to print. What’s more, whereas the San Diego robot was made using a US$1,000 printer, the Edinburgh bot is made by a ~$500 open-source platform called the Flex Printer, which is constructed from off-the-shelf components.

The University of Edinburgh

Like its American predecessor, the Scottish robot is printed entirely out of soft, flexible thermoplastic polyurethane (TPU). That material starts out as a filament which is heated to the melting point, then extruded out of a print nozzle to build up the robot’s body in successive layers.

Because the molten TPU is so soft, however, it’s notoriously difficult to work with. For one thing, instead of lying in nice straight (or curved) lines when being extruded, it has a tendency to buckle off to one side or the other. The scientists describe the extrusion process as being like “trying to push on a piece of string.”

Additionally, before the molten TPU cools back to a firmer (yet still elastic) consistency, the force of gravity causes it to droop. This is particularly problematic when printing horizontally suspended bridge-like structures, as the drooping action may actually keep the layers of TPU from connecting with one another and fusing together.

The buckling problem was solved mainly by switching to a wider-diameter and thus sturdier TPU filament – 2.85 mm as opposed to the more common 1.75 mm. Doing so made the extruded material seven times more difficult to buckle, when it was attempted.

The drooping problem was addressed by actually turning the 3D-printing process upside-down.

Instead of dropping the TPU down onto a print bed, the Flex Printer’s nozzle pushes it up onto one, which the material sticks to until intentionally released. In this way, gravity actually helps the layers of TPU fuse together, as each sticky new layer is pressed onto the hanging layer that came before it.

Once the printing process is complete, the print bed is flipped over so the robot is right-side-up.

The bot is then hooked up to a device known as a pneumatic ring oscillator, which delivers a pulsating 2.25-bar (32.6-psi) air current into channels within the robot’s body. The air pressure sequentially triggers two ligament actuators in each leg, which move the limb laterally, along with one foot actuator that lifts the limb off the ground.

Soft-bodied, 3D-printed, air-powered robot in action

Although the specific robot made in the study is really just a demonstrator, it is hoped that the open-source technology could help boost the development of soft-bodied robots used in applications such as exploration, medicine, plus search and rescue.

“Using our new platform, anyone can now easily print things which were previously thought to be impossible,” says University of Edinburgh engineer Maks Gepner, who led the study along with Prof. Adam A. Stokes. “Without the long-standing manufacturing and design bottlenecks holding it back, we believe soft robotics is ready to make a major real-world impact.”

A paper on the research was recently published in the journal Device.

Source: The University of Edinburgh